Rehabilitating Stanley, an Alpaca with Berzerk Male Syndrome

Last fall, I saw a lone alpaca on kijiji for sale and my heart went out to him. He was obviously the only one, and had been guarding sheep. Alpacas aren’t really great guard animals — they are not large enough and can’t really defend themselves very well against a predator like a coyote, especially when they are alone.

So we hitched up the horse trailer, filled up the truck and went north to a farm to get him. He was a lovely grey colour and I was excited to meet him! When we got there, we were surprised by how small he was, and even moreso, how friendly. The little 4 year old girl who lived there could hug his neck! We didn’t have a single alpaca among our 9 that would let anyone hug their neck!

When we got Stanley home, he continued to be surprisingly friendly and for those of you who know alpacas, you may be seeing the signs. I was not worried, although a tiny remote part of my mind was aware that he could have Berzerk Male Syndrome.

Berzerk Male Syndrome, or BMS, is when an alpaca — nearly always a male — starts attacking its owners. It can charge, body check, hit, bite, tackle and even try to mount and mate with people.

Stanley was friendly and enjoyed going nose-to-nose with us, and was often nearby. He really didn’t cause any trouble until the spring came. He rather suddenly got frisky and wanted to fight us — to wrestle the way that male alpacas do when they want to see who is dominant. The first couple of times he attacked without any warning, taking us very much by surprise. Darren got tackled 6 times — sometimes against a wall, often out in the open and ending up on the ground.

I got tackled twice. The first time, I thought Stanley wanted to go nose-to-nose, so I leaned toward him… and he just came at me full speed, hitting me with his chest. Luckily, I was near a grainery, so I landed against it, grabbed a nearby fence and was not hurt. I shouted at him, and kinda whacked him (don’t worry, it wasn’t that hard) on the back with my free hand. The second time he attacked, I was in the open and he knocked me down and then leaned down and bit my shoulder! I got up as quickly as I could and got away, but wow, was I ever rattled. The bite left a mark like a bruise but did not break the skin. I was lucky.

I decided it was time to research Berzerk Male Syndrome. Until then, all I had known was that it was caused by over-cuddling. You know all those pictures you see on the internet of people cuddling alpacas? In many of them, the alpacas aren’t really enjoying it, and in the others, they might be on the way to developing BMS.

I found an article that said BMS is caused by an alpaca bonding to humans instead of its alpaca mother. This is more likely to happen with bottle babies — hand-fed by humans — or general over-cuddling. You may had heard of baby birds bonding to the first thing they see upon hatching — if it’s a person, that bird will be your best friend for life. In the case of alpacas, the alpaca sees itself as a person, or sees people as fellow alpacas. The result is quite awful. Here’s another good article.

Although we were very discouraged and a little upset that the people selling Stanley didn’t tell us the truth, in some ways, I didn’t blame them. They had 3 kids including a newborn, a number of sheep and beef cows and were just trying to make everything work. They probably didn’t know what do to about Stanley and were afraid of him. I was also afraid, but did not want to give up on him. I believed that he could get better, so we set about a “training program” for him and for us to see if he could be rehabilitated. I had not heard of others doing this; some online material said that castration would help but others said that euthanasia was the only solution. I didn’t want to accept that, but we did decide to castrate him. I had hoped to breed him, but what if — what if — BMS was hereditary? I was not going to take that chance. We could not wait until breeding season either. By the middle of May , we were becoming afraid to walk around the yard. Breeding season wouldn’t be until June.

We arranged for his special appointment with the vet and she graciously allowed us to shear Stanley while he was looped up on sedative. His previous owners had trimmed his back and some of his neck, but he still needed more shearing. In fact, he had so much fibre growing on this belly and between his legs, when we got him, he had a poopy bridge of fibre going from one back leg to the other. I was able to cut that off the first day we had him, because he was so willing to stand still and let me near him. So, Stanley got “fixed” and we hope that it would fix the BMS as well.

Castrating him definitely helped, but I think our behaviour changes were also critical to our so-far success. Let me try to break it into chunks that make sense.

- We stopped giving Stanley any extra attention. No more nose kisses, long eye contact, pets or long conversations (if you know what I mean). I would say good morning to him, but then also say good morning to every other alpaca around, looking at each one in turn. Stanley needed to feel like a part of the herd, and not a person. I do not believe that an alpaca with BMS could be rehabilitated without being in a herd of at least 6 others of the same gender. The hardest part of this rehab was not obsessing over him and if he was going to attack.

- We kept an eye on him and we went around him. We tried to think like an alpaca — what sort of behaviour could be seen as aggressive? Meeting face-to-face on a narrow path — definitely. So we go around. Initially, I would give him 20 feet of space, going off the path that far to appear non-aggressive to him. Now, 5 feet is enough buffer, but I still go around. If we are out in the open yard, and he is standing between me and my destination with his head to the right, I go around to the left, around his bum. In no way do I want to be seen as starting something. There were times when Stanley was so frisky, we walked on a trail through the bush to avoid the yard completely to go around him.

- We don’t continue the fight. When he would start something, we’d try to get away and stop the fight, rather than retaliate or try to “hold him still.” If you are an alpaca farmer, you know that holding them still can be hard. It can definitely feel like wrestling. A couple of times, I witnessed Darren getting attacked and had to remind him to let go and get away, not try to hold on to or subdue Stanley — that is too much like two males wrestling. Again, thankfully, we have 7 other males, so usually one of them would get interested in what was happening and as soon as we could get free, they’d get in there — either to save us or to have their own wrestling time with Stanley. Rupert, Pigpen and Frankie are all young enough, they don’t want to be left out of a summer wrestling match!

- We watched for the signs. For Stanley, it became obvious when he was frisky. He would look straight at us, perhaps with his chin slightly up, and — the biggest sign — his tail would be slightly lifted. He looked like he was making himself tall. When we saw that, we knew what he was thinking and we backed away, raised a “stop hand,” and shouted NO at him. He understood that. I also tried not to raise my chin — that’s alpaca body language for “I’m going to spit at you,” or “I’m annoyed with you,” so I did my best to keep my chin down. Not that spitting was part of his fighting; it was much more of a full-body tackle. But I did not want Stanley to think I was an alpaca in any way, so I kept my chin level or slightly down.

- We stayed calm and tried to be proactive. One afternoon, I was working in the shop. I knew he would be curious and maybe get too close, and that could lead to some wrestling. So I put a ladder across the shop door opening. This way, he could look but I could relax because I knew he couldn’t get in. Sure, he could have jumped over it, but he never had that much hatred in his veins. He just wanted to fight because fighting is what male alpacas do to establish who’s dominant. We needed him to know that WE WERE HUMANS, not alpacas, so we were not going to fight him and we could all live together peacefully AND we humans were in charge. Peacefully in charge. It is hard when there is a pattern of attacking to stay calm, but it is important. Alpacas are very empathic and they’ll feel your nerves.

- We changed some of our physical signals. Normally, to move the boys in, I put my hands out to the side like a letter T or a walking fence panel and they know to walk the other way. I can corral them pretty easily, especially if they can see the open gate they are supposed to go through. I was afraid that Stanley might think me putting my arms out to the sides was an invitation to a hug, so I never did it. Sometimes, if he didn’t want to go in, he got to stay out. Other times, I was able to “shoo” him in with a casual, low-down forward motion of my hands. One time, I used a broom handle held horizontally at waist level and he seemed to get the message. I absolutely do not go nose-to-nose with him, even if there is a fence between us. He sometimes wants to, but I don’t. It’s too familiar, and I don’t want to remind him of people who hug and kiss him. One time I had gotten too close, I held my forearm horizontally in front of my body at about boob height, and he understood that as “stay back” body language.

I wish I knew Stanley’s backstory, but I don’t. I wonder if he was a bottle baby. I wonder if he caused trouble at his first farm, was sold to the sheep and beef farmers we got him from, and he was okay for a while and then got aggressive as he got older? At the farm with NO other alpacas, he had to fight the people — maybe he even tried with the sheep but that wouldn’t work either. That’s another reason alpacas need to be in groups of at least 3 of their own gender.

Let me share a few other surprises we had. When he is wearing a halter and on a leash, he can still lunge at you. After we got him fixed, we had to keep him separate for several days to heal, and the last day, he was tired of going in that other barn and didn’t want to. We tried chasing, but ended up haltering him and he lunged at Darren. Perhaps it might work to have 2 people with leashes the leashes taut, but this would require a lot of coordination and also has the hazards of all those leashes to get tangled in. You really do have to think ahead when you are planning some farm activity you’ve never done before.

Please, if you are an alpaca farmer reading this, or considering getting alpacas, DO NOT cuddle them at any age. Keep cria with their mothers or other females if their mother has died. We had to bottle feed one cria, but we did not snuggle him before or after, and I’m so glad that Frankie is totally normal!

Also, don’t take this article to be everything you need to know about working with a berzerk male. Some of them truly may not be savable. I don’t think you can be successful if you only have a couple of alpacas. My other boys were crucial in teaching Stanley how to be an alpaca. How could I possibly do that? The herd showed him what behaviour was acceptable. How do I know they learn from each other? Pigpen briefly adopted a couple of Stanley’s behaviours and we stopped those right away with strong language, and Pigpen has never done it again. So they can definitely learn from each other, but as I said before, the humans on this farm are peacefully in charge.

I’m happy to report that Stanley has been well behaved for quite some time. He is still very curious and is often nearby, watching us work as if to help. But then he loses interest and wanders off or goes back to grazing randomly on the yard! Yay! We are not the focus of his attention and he is not the only focus of ours. He is still a bit unpredictable, intensely curious of and occasionally aggressive with new people. He recently chest-bumped a wooden fence because a friend of mine came over for the first time. She was giving him attention of course and he lunged at the fence. A few months ago, he ran across the yard and would have tackled another friend of mine (a horsewoman who is very tough and would have actually been okay) if I had not intercepted and stopped him with my hand against his neck!

Even though we haven’t figured out everything there is to know about rehabilitating a BMS alpaca, I wanted to share what we have learned. I hope this may help someone out there. Don’t cuddle your alpacas. Don’t knowingly get a BMS alpaca unless you have a herd and lots of experience with healthy alpacas. Berserk Male Syndrome is serious and you can be seriously hurt. Don’t give up too soon; for Stanley, this progress has been over several months and we have had him over a year. And don’t be afraid to admit defeat and get help from other farmers, or euthanize him. But please don’t lie and rehome him.

DIY Infinitely Adjustable Woven Watch Strap

I still enjoy wearing a watch. I know, I’m weird that way. It’s just nice having the time so conveniently located on my arm, without the need to get my phone out and hit a button. I’ve replaced the battery on this little one SO many times, and have also had to replace the strap a few times too.

The other day, I thought, why not use a narrow-band weaving technique to make a watch strap? Turns out, it was really easy and I love the strap!

Materials

- Thin, non-stretchy yarn

- Darning needle

- Loom or large hardcover book

- Marker or highlighter

- Pencil or small dowel

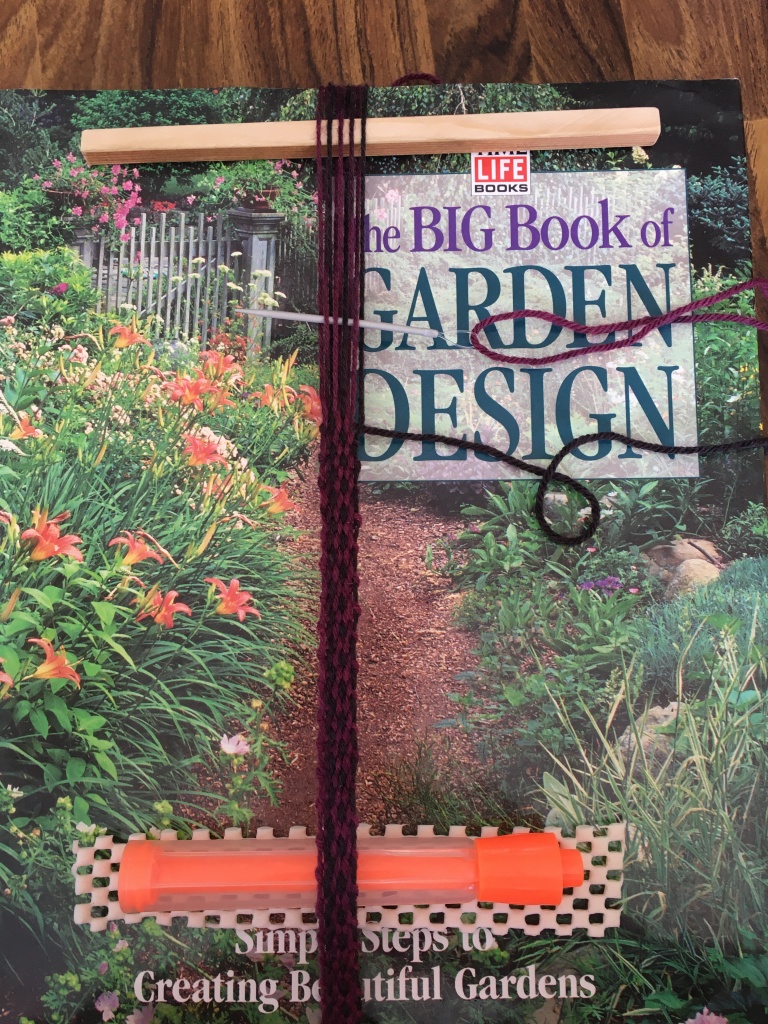

I used this small 3D printed loom to make mine. The end pieces (beige) are what’s 3D printed and the rest of the loom can be built with dowels or PVC pipe.

I realize a lot of people don’t have a loom, and I’m a big fan of DIY and rigging things up, MacGyver-style! So, I made a loom out of a large hardcover book:

I just wrapped the yarn around the book once and tied it. I then wrapped it around 8 more times for a total of 9 warp strands and tied it to secure it again. You can make it however wide you like (within reason).

Pass the pencil or small wooden stick (mine is a square dowel) at the top over and under the warp to create one shed. Slide the marker or highlighter (something thicker than a pencil is all you need) under all the strands at the bottom to lift the weaving up so you can insert the needle. Below, you can see me weaving the second shed, which is the opposite of the open shed, but having the open shed helps you see which yarn to pick up.

To weave, just go over-under with the darning needle and pull the weft through. I’m using the same yarn for warp and weft although this isn’t required. Whatever you use, make sure it doesn’t stretch much. I used wool sock yarn for mine. Below, I’m working on a wider one for my grandma.

The trick is to pull the weft strands through and carefully watch the edges, and to pack the weft strands down consistently. You can use the needle itself, but I have also made myself a small shuttle that works great. It allowed me to pack the strands a lot tighter (perhaps you can see the difference between the photo above and the photo below).

When you pull each strand through, be careful to tighten the loop the same each time.

In the image above, you might notice that the warp yarns sort of stack up. I found if I pressed them down slightly, I could separate them again — see photo below:

You’ll have to sew the ends to prevent the weaving from unravelling. A basic hem stitch for weaving works, or use a sewing machine.

I hope this is enough to go on to set up a loom and create your own narrow band watch strap! I reused my watch hardware but you could sew velcro on if you wanted. Either way, the band is infinitely adjustable — no more looking for the best hole on the watch strap, or settling on one that is too loose because the next one would be too tight. Just nudge it over one yarn and voila!

Want to see my first narrow band project? I had started it using the backstrap method but later mounted it to that loom. I also made that nifty shuttle to really beat the weft down. The edges are not very even and my conclusion about this is: tension is simpler to keep consistent if you pull each strand TIGHT. And using all the same yarn would have probably worked better too. Anyways. I was using a diamond pattern and a pink ribbon yarn, which worked okay. I haven’t been using it as a lanyard as planned because I’m a bit embarrassed by it. I know I can do better and I want to make another one! 🙂

So don’t worry if your first band is a bit rough too! It’s probably not worse than mine!

Take care everybody!

My Handsome Alpacas

I love alpacas. They are the sweetest, intelligent, curious critters! I wanted to introduce you to each of our guys (and gals) and tell you a little about them.

Fozzie

First of all, there is Fozzie. He is one of the first alpacas we got. What a guy!

In the portrait below, he is in a fairly fluffy state — shearing day was probably coming soon. He’s actually quite a slender fella! I just have to say…

You see this:

And I see this:

Ziggy

This. Guy. So handsome! Look at that roman nose! Be still my heart! I mean, who is handsomer? Ziggy or this guy?

Seriously, Ziggy is right? And unlike his name, he is very chill and steadfast. He has nerves of steel, that Ziggy. Just like Fernando Alonso.

Boeing

Boeing is an amazing guy. His fleece is to die for. Long. So soft. A bit crimpy. Luscious. But he hasn’t mastered the finer points of life. There’s an expression – like a bull in a china shop. Let me suggest a new one – like Boeing in a mud puddle.

You see this…

And yes, he needs a little dental work. But don’t mention it, okay? He’s sensitive about it.

But he’s still a handsome guy, you know? Like he reminds me a little bit of this guy…

I see this…

That is the only picture on the internet of Benedict Cumberbatch showing his teeth, by the way. It was hard to find.

Alex

Alex is such a handsome boy, in a slightly punk kinda way. I mean, he has 3 different colours of fibre on his head, c’mon! He’s hard to get a good picture of, though, because he’s always shredding a curve on his skateboard. Okay, maybe not.

You see this…

I see this…

Because Aragorn was a strong and brave and smart leader! And Alex is all those things too. Especially the smart part. And he does seem to be the herd’s benevolent, calm leader.

I just can’t resist showing you this photo of Alex as a little fella!

Frankie

So, I didn’t mean to name Frankie after a mobster. It was just the name that seemed to fit. He is SO handsome, though, and I can never forget all the times I bottle fed him!

But he’s all grown up now! And he’s handsome like his papa, Ziggy, but tall and slender like his mama, Daisy. Slender when he’s sheared, that is.

You see this…

But don’t be misled by the floof. He’s so serious. Studious, sometimes. Stoic. What a guy. You see Frankie and…

I see this…

And little Frankie, only a few days old here:

Pigpen

Just look at this face! The fluff! Our little Pigpen has grown into a big, handsome boy. One who really needs a haircut in this picture!

You see this…

He is so much like his papa, they can be hard to tell apart. But he has his mama’s teeth (thank goodness), and his papa’s beautiful fibre. He still likes to go nose-to-nose with us sometimes, and we often see him with a spot of green on his gorgeous white fibre because someone spit on him! He was probably asking for it. He’s full of spunk and life and he reminds me a bit of…

I see this…

I know you can see the resemblance.

Rupert

What can I say about Rupert? He’s kind of the class clown, but I think he’s just young, y’know? He’s growing up, definitely. Like emotionally. But I think he’s as big as he’s going to get. He takes after his papa, Ziggy, in that way. He’s a small guy, but he can hold his own. He most reminds me of…

I mean, come ON! So handsome.

Last but not least, our new guy.

Stanley

We’re still getting to know Stanley, since we adopted him less than 6 months ago! He’s super affectionate, loves people, is very curious, and even seems to enjoy being petted. But he’s never pushy, which is great. He loves giving real, lip-to-lip kisses. What a guy. He’s gentle and thoughtful too. His grey coat is the most beautiful colour and I look forward to shearing him (or getting him sheared! Let someone else do the work this year!) and spinning his beautiful fibre.

He reminds me of the handsomest grey-haired guy I could think of:

This has been fun! What do you think of my choices? Can you see the resemblance in any of these guys?

Oh wait, what about the girls!?!?

Marley

Our Marley. What can I say about her? She’s a nice alpaca 364 days a year. On shearing day, she is the most uncooperative ‘paca I know. She will just refuse to walk. She’ll lay down and that is that. Getting her up again is… difficult to say the least. She’s a big girl — probably in the top 5% for alpacas. And stubborn. So stubborn. Last year, we sheared her laying down because there was no moving her.

She is beautiful though. Here’s who she reminds me of!

Daisy

Lastly, our beautiful Daisy. We’ve known her since she was born, and she was the cutest. She’s always been a supermodel. Absolutely beautiful. Slender and tall. She’s pretty even-tempered too, as long as you don’t try to touch her. She hates being touched or petted in the slightest. Daisy will leap out of the way if she gets an inkling that you might try to reach out and pet her. So I generally don’t! It just stresses her out too much.

She’s been a good mama to Frankie and Rupert. (Ziggy is their papa. They have a thing.)

You see this…

I’m so proud of her for being such a good mama. When Frankie was born, he needed help and we actually milked Daisy! I am probably one in a million on a list of people who have milked an alpaca!

I think miss Daisy is really ticklish, and that’s why she’s so jumpy! Shearing her last year, she would jump a little each time we touched her. Maybe more handling would help, but I don’t know.

I see this…

Beauty is definitely in the eye of the beholder, and it’s ever-so-true for me and my alpacas.

Have a great day everyone!

Remembering Julie Rivet

A year ago today, a good friend of mine, Julie Rivet, passed away. I met her when I worked at Science North as she was hired shortly after I did. We became friends and would often eat our lunches together outside the third floor, on the rock facing Ramsey Lake. Before long, we both joined the Sudbury Canoe Club and learned to kayak together. We often borrowed the kayaks and went on Ramsey Lake after work, and by “often” I mean 4 or 5 times a week!

We got much closer when I needed a place to live for a month and she offered me her spare room. I appreciated her kindness so much. I was frazzled and needed somewhere safe to land, as they say, and she was such a wonderful friend.

Before I left Science North, she left to work for Parks Canada. Although we didn’t talk often, our friendship lasted. I visited her twice when I was in Ottawa and we picked up right where we left off. If I needed advice, she gave some of the best. If I needed to listen, she would do that too.

After living and working for Parks Canada in Marathon, ON, she applied on the job in Ottawa. After a few years working there, her migraines started getting much worse. Before everyone was doing it, she worked from home so that she could at least work some half-days and if the afternoon was consumed with a migraine, she had at least done some work. Parks Canada was great to her, especially since the cause of her migraines could not be determined.

In September of 2022, one of her migraines also brought on a bout of dizziness and vertigo. Her sister suggested she go to the hospital, since this symptom was new. A CAT scan revealed a large brain tumour. She stayed at the hospital and within days, she had more scans and met with specialists. Her brain tumour was “considerable” which I later learned was about the size of a fist. It’s unreal.

She had a difficult and extremely risky surgery within days of the tumour being found. She survived the surgery and could walk, talk, see and hear. We all were able to exhale again — her life had been in the balance and we won. But her struggles were not over. And doctors said she would be lucky to live six months.

She underwent various other cancer treatments, many of which were far worse than the cancer itself. After a few chemo treatments, she did the incredibly courageous thing — she stopped going.

The days were difficult, and for as much as Julie suffered, her man, Greg suffered too. They had been together for 17 years when the diagnosis came, and while in the throes of her brain swelling, they were married in a very small ceremony at the hospital in Ottawa. Her sister had a white dress that fit. Flowers were ordered, and officiant was arranged from the city of Ottawa. Covid was still going strong and the city had not done any weddings all year. Thankfully, the ceremony was broadcast on Facebook live, so I was able to watch! I was so happy for them both. I cried a lot; it was so bittersweet.

Brain cancer is terrible. I would not wish it on my worst enemy. Julie had good medical care, but as it was, she was anxious, afraid, and confused much of the time. Greg managed her many meds and made sure her medical team knew her condition. She was in and out of hospital several times, and I was lucky enough to visit her in December 2021, the day before she got to come home from one of her stays.

I don’t want this blog post to be about the cancer; I want to tell you about Julie. She was always caring and considerate as a person. She worked hard and was a good supervisor too — thoughtful, clear, and a good communicator. She saved me from making one interpersonal mistake when I asked for her advice. She was so lively! We went on many hikes together, in addition to all the kayaking. She was adventurous! She and Greg moved to Marathon, a northern Ontario town of 3200 people for her to start her new job at Parks Canada. Later, they moved to Ottawa so they could be closer to family. She took pottery classes and learned to make beautiful jewelery with natural stones. She loved to bake cookies, muffins and sweets. She had a blog for a while too, where she posted about her adventures, thoughts, recipes and so on. She called it Musings of a Northern Girl.

I wish everyone could have a friend like Julie. She was fun, kind, open and generous. She is missed by all who knew her. She lived the 6 months they gave her well.

Here is Julie’s obituary. and just so it doesn’t get lost, the text is pasted below:

Julie Claire Nathalie Rivet passed away on February 5, 2022, after a valiant battle against cancer. Surrounded by prayer, and her loving family, her faith guided her peacefully home to the arms of Jesus.

Julie was born in Sudbury, Ontario on May 2, 1971 to Jacques and Paulette Rivet (Vincent). She graduated high school from College Notre Dame in 1990, earned her degree in biology from the University of Ottawa, and Diploma in Parks and Outdoor Recreation from Sault College.

Julie was passionate about learning and education, which she carried into her career as a staff scientist biologist at Science North, and as a dedicated promoter in Parks Canada. She also had an entrepreneurial spirit and creativity that she showcased in her jewellery making business. Her love of nature, adventure and travel was shared by husband, Greg Wright, with whom she experienced the world.

She and her selfless nature will be greatly missed by Greg, and all her family and friends. She is predeceased by her father Jacques and will be kept in the hearts of her husband Greg, stepdaughters Mandy and Kristen, mother Paulette, along with her siblings, Francine (Atul), Daniel, and Ginette (Wayne).

Funeral Mass to be held at Holy Redeemer Catholic Church, 44 Rothesay Drive, Kanata, on Tuesday, February 8th at 11am. Due to Covid protocols, in person attendance will be strictly limited. To RSVP, please use the tab below to register. For those who wish to participate virtually, the Funeral Mass will also be available to be viewed LiveStreamed. Please visit Holy Redeemer Catholic Church website at: Holy Redeemer Catholic Church , use the tab Our Parish, then click here to watch mass, and scroll to the links provided to view the Mass by Facebook or Youtube.

Calculating Yardage Needed for a Triangle Loom

A friend of mine sold me a beautiful triangle loom from Dewberry Ridge. It is so wonderfully versatile because you can put it together into many different sizes, and it’s super sturdy once assembled, and really well made.

If you are familiar with triangle looms, you know how the strands run on a continuous strand weaving. They go around each top nail, then around a diagonal nail, across to the other diagonal side, then up to the top.

If you are new to triangle looms, I apologize if this blog post may be a bit confusing! Go search it on YouTube and you will find lots of helpful videos. If you know tri looms, I hope this helps you plan your weaving!

The question of yardage. How how much yarn do I need?

I figured there’s got to be a way to calculate how much yarn is needed to make a full shawl. It shouldn’t be that hard! I made a shawl using yarn I spun from 2021’s Vlogmas advent calendar which I ordered from Jillian Eve, and it turned out quite nice!

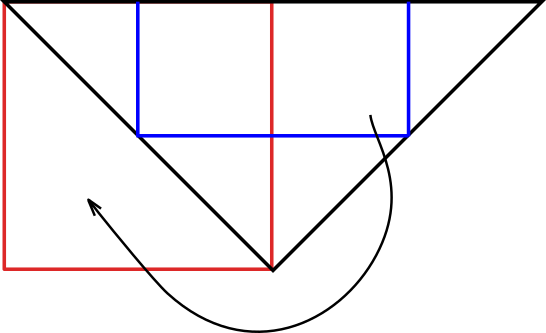

I didn’t have quite enough yarn, but I also hadn’t been keeping track of each day’s spinning yardage. So the yardage required was a big question mark for me! In order to finish the shawl, I spun up some wool from a monthly fibre club I have joined. That’s the mostly pink section in the middle. In the image below, you can see the shawl near the beginning and follow the path of the yarn.

Calculating Yardage

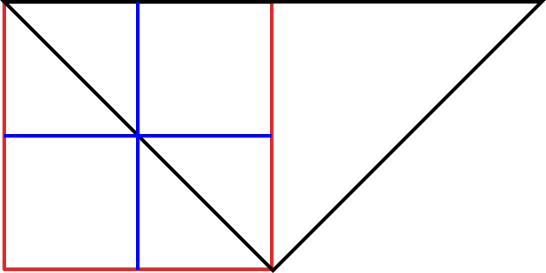

I thought I might have to use calculus, and I haven’t used that since university (which was a long time ago! :), but then I remembered a little basic geometry that says a triangle is half a square. We can move the right side virtually over to the left and just calculate on that half as if it were a square.

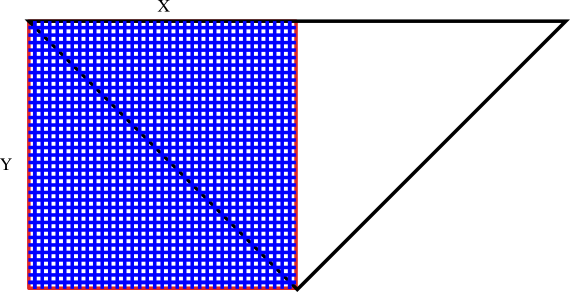

So let’s consider the area in the red square.

We have to figure out how many strands there are. How will we do that? Easy. We just count the nails! Across the top, the nails give us the vertical strands…

And thanks to the diagonal nails, we get the horizontal strands.

There are X (some number) of vertical strands and Y horizontal strands. The Dewberry Ridge triangle loom is made so that you can combine different sections to make different size shawls. At it’s biggest, it is 7 feet across the long edge. At its smallest, it is only 3 feet. I love how adjustable it is! Anyways, for whatever triangle loom you have, count the nails along one of the shorter (diagonal) sides. There will be the same number of nails along each of the 3 sides — this is universally true for all tri looms.

For example, let’s say I decide to count the total number of nails across the top (long) edge and I get 100. I am only going to concern myself with the left half, so X = 50. Since there are the same number of nails on each edge, Y must equal 100 and I don’t have to count them if I don’t want to.

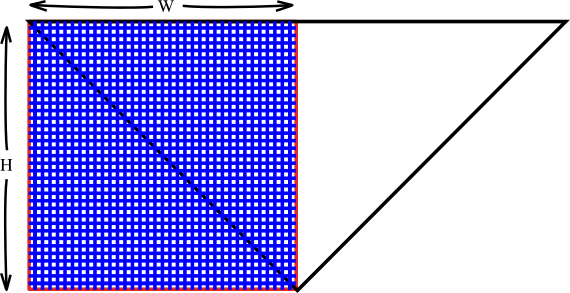

Next, we just need to know how big the loom actually is — in other words, how long the strands are. On the drawing below, W is the half-width and H is the height.

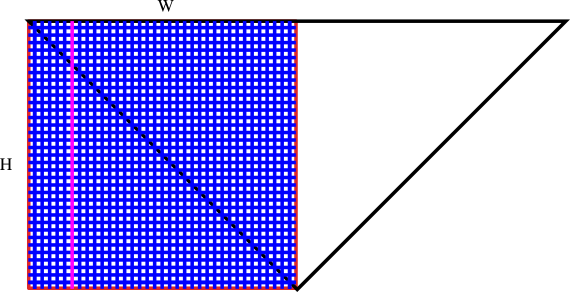

Now you may be thinking, but Teresa, the bottom part of the strand isn’t really on the loom? It’s floating in mid-air, isn’t it? Like the pink strand below:

But, remember that we took the right side of the triangle and moved it to the left. So the floating strand belongs on the right, albeit on a different row.

So, every portion of a strand that seems to be floating, represents a strand from the right side.

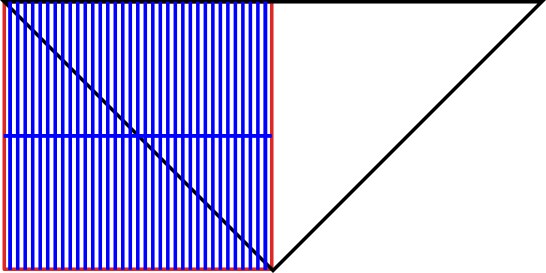

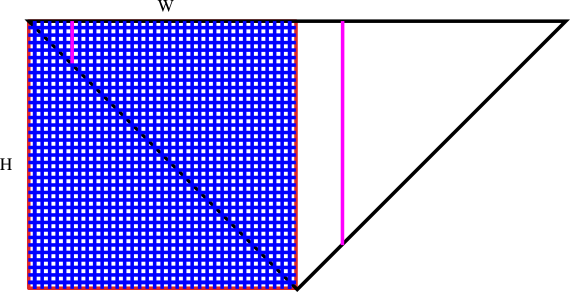

Look closer at the in-progress photo and you will see that each nail across the top actually holds TWO strands. So will need to multiply the X number by 2 after all.

The calculation

To recap, the number of nails on one side = Y.

The number of nails along the top edge of the square = X (which should be half of Y)

The height of the loom is H and the width of the square is W (which is half of the overall width or wingspan of the loom).

Therefore the calculation for yardage really is as simple as:

Yardage for a triangle loom = all the vertical strands + all the horizontal strands

Yardage for a triangle loom = 2(X x H) + (Y x W)

or if you only counted the nails on the diagonal side, then remember that the number of nails on half the top edge will be half the diagonal (or X = 1/2 Y). So the formula becomes:

Yardage for a triangle loom = (2(Y/2) x H) + (Y x W) which simplifies to (cross out the two 2’s)

Yardage for a triangle loom = (Y x H) + (Y x W)

Or in plain language, for those less mathematical:

Multiply the number of nails on a diagonal side times the height. Write that number down somewhere. Then multiply the number of nails on the diagonal side times the width of the square (half the wingspan of the loom). Write that number down. Add the two numbers you wrote down and you will know how much yarn you need to weave a full triangle!

It would probably be wise to add 10% extra for distance to wrap around the nails and for contingency and take-up, the fancy term for over-and-under-ing! Don’t forget that you need to start with loose tension and it will tighten as you go. So once you have your total yardage, multiply times 1.10 for a new amount which will include the 10% extra.

Leave any questions in the comments and I’ll respond as soon as I can. I’d love to hear your results if you use my formula! Whether you are using handspun or store-bought yarn, happy triangle weaving! 🙂

DIY Dog Coat That Closes Up the Back

Hi everyone! My friend Mark has a small dog named Dexter. He’s a little uptight — the dog, not the friend — and he occasionally nips at people when he’s not comfortable (again, the dog, not the friend). 🙂 This made it very challenging to put on store-bought dog coats that do up right under that little biting face! You know the type of coat, with a zipper up the front.

So, Mark asked me to make a coat that would do up the back, and hopefully, be really easy to get off as well. Velcro was a good idea, so that it would be really fast and easy to take off. And can I say that Mark deserves many kudos for taking on this dog, as it was his ex-wife’s dog and she never disciplined it as a puppy and somewhat created the monster. I mean, he’s not a bad dog… he’s just a little feisty!

I had a hard time finding a pattern online, but I did find one made from a Carhart coat — genious!

Dexter is quite small, so I needed to make a pattern, measured to fit. Mark also asked if I could insulate the coat with alpaca fibre, similar to the alpaca parkas I have made before. No problem! Look at Dexter showing off his coat!

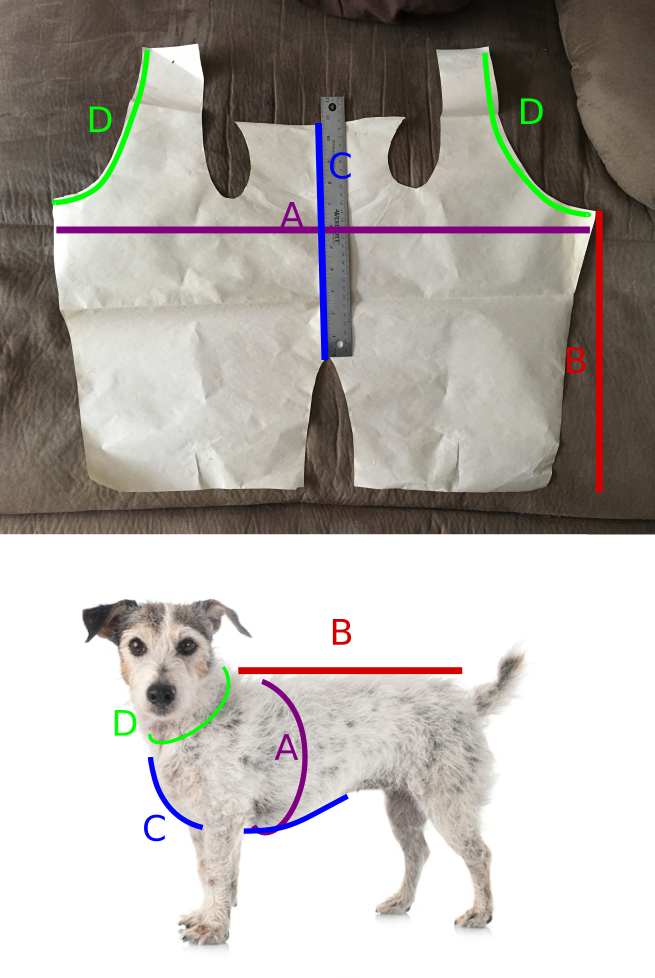

Mark managed to measure around his dog’s middle (see A below) and length of his back (B). If your dog will sit nicely, the other two measurements would be nice to have, but they aren’t actually necessary.

This blog post isn’t meant to be a full tutorial, but hopefully with some sewing or crafting experience, you can make your own dog a coat. Start with whatever fabric you have, perhaps doubling it up if you want to make a warmer coat. I used red polar fleece (Dexter’s favourite colour!) and light purple cotton cloth with carded alpaca fibre sandwiched between.

Start by taking the dog’s measurements.

A: the distance around the chest/rib cage of the dog.

B: The length of the dog’s back from where the neck rises to the tail (or slightly before).

C (optional): Distance from the collar area between the front legs to the middle of the tummy (for a female dog, this number might be a little bigger, but it still should not be too far back).

D (optional): Neck circumference.

Making the pattern: Cut a piece of paper that is A wide and approximately (B x 2) high. For a male dog: mark a vertical line up the center and make a center cut-out for the dog’s peeter. You don’t want him peeing on his coat! The length of the cutout should be about half of B. In the end, my cutout was quite a bit wider than the pattern, so you can make yours appear wider than my pattern piece (see below).

See above how wide the peeter-opening is! And you can see how I hand-quilted mine. There’s alpaca fluff in there!

When I made my pattern piece, I just kinda eyeballed the shape of the top part, where the front leg cutouts are. You can see that it’s not perfectly symmetrical. The tutorial for the carhart coat shows the shape when folded, and that may work better for you to make it symmetrical.

Once you have the peeter-cutout marked, your C measurement would go straight up to determine the height of the center part which ends up under the dog’s chin.

Then, if you take the dog’s neck measurement (D) and divide it by 2, that will guide how the neck curves (D) look and how high the overall pattern piece is. I just eyeballed the front leg cutouts once I had all the measurements marked.

When you are satisfied with the pattern on paper, cut it out. You can try it on your dog by taping the piece together — refer to the diagram below — yellow to yellow, orange to orange, cyan to cyan. If it fits reasonably well (or slightly baggy), you’re on the right track. Since I couldn’t try it on Dexter, I had to proceed on faith that it would fit! The first one I made from super-thick polar fleece was too small, argh!

Cutting the cloth: Lay the pattern on top of the cloth (or pin in down) and cut it out about a half-inch bigger on all sides (seam allowance). This will let you fold it over and make a nice edge. If you are working with a polar fleece fabric similar to the red I used, you don’t have to worry about fraying, which kind of makes the fold-over hem optional, but it will make the coat look nicer. Be absolutely sure to cut the detailed area at the top of the pattern with a seam allowance, especially adding some overlap space where the yellow lines are (see below) and at the red lines for the velcro to overlap. Also be sure to make the cutouts for the dog’s front legs big enough. You’d hate for those to be too small. When in doubt, go a little bigger.

Hopefully, you can see how a two-dimensional paper object can become a 3-dimensional piece of clothing! I’m so pleased with how it turned out! The neck is roomy and he seems to really like it.

Assembly: I suggest matching up the two yellow lines and sewing them together, and then centering and matching up the orange and cyan areas and sewing them together. That’s the tricky part done!

The red fleece I used was a bit stretchy, so I made the tight corners around the leg openings work, but I remember having to cut a few notches too. You’ll figure it out! Below is a view of the dog coat from the top, which shows how the chest area comes together.

And next, the dog coat upside down:

Yup, there are some puckers and I’m okay with that!

For the top closure: I chose to sew the hook velcro along the long B edge on one side and the fuzz velcro perpendicular on the other side about 2″ long, to give Mark the maximum ability to adjust it.

I hope this makes sense and if you have any questions, leave them in the comments and I’ll do my best to answer them! Thanks to Mark for the photos!

Being Respectfully Independent

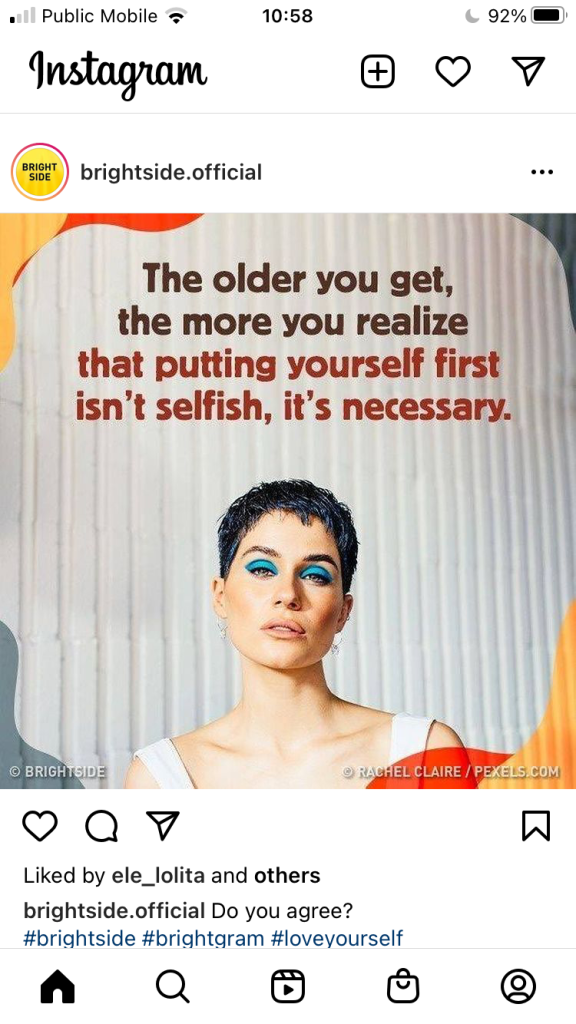

This graphic triggers me on so many levels.

First of all, the photo. I don’t see how bright blue eyeshadow has anything to do with putting yourself first. The model also has a facial expression that seems to say, “go ahead, piss me off. I love being annoyed.”

But, I know it can be hard matching a photo to an idea. The model and photo don’t match the idea very well but let’s go into the text now.

The older you get, the more you realize that putting yourself first isn’t selfish, it’s necessary.

– Brightside official

If you actually lived by this, you’d find yourself eternally chasing the need to be first all the time. You would drop everything else to make sure your needs are met, right now. You would never help someone else until YOU are taken care of. You would never inconvenience yourself to participate in a work bee, help a friend move, work a job that was slightly unpleasant, and so on! Putting yourself first is chasing a dream you can never reach! My main issue with this philosophy is the word “first.”

Every moment, the very next thing you do is first. If you followed the advice in this graphic, every moment, you would be fully focused on yourself. That is a formula for unhappiness.

You would constantly be assessing how happy you are. Could you be happier? Is anything getting under your skin, annoying you? How can you put yourself first right now? Who or what is in your space, interfering with what you need to be the happiest you can possibly be? This line of thinking becomes so self-centered, there’s no possible way to actually be happy.

It’s ironic that this philosophy is supposed to increase one’s happiness, but following it will do the exact opposite.

So don’t believe every tidbit of wisdom you see on the internet! Many are actually materialistic or selfish dogma… with no possibility of making us happier or more at peace. Wear blue eyeshadow if you want — doing so won’t hurt anyone else — but don’t obsess about your own happiness every moment of the day. Put yourself first from time to time, but thinking of others and being a helpful person will ultimately make you so much happier!

Think Like a Farmer

I grew up on a small, mixed farm in western Canada. My mom and dad raised beef cows, chickens, sheep, and we even had 2 dairy cows for a while and a horse. My dad grew all the feed for the livestock he raised. At harvest time, there was hay to make, grain to combine, baling to be done and all the other complications of trying to bring in a crop before winter sets in.

If you didn’t grow up on a farm, you probably have no idea what “other complications” I am talking about. And so you might think it would be fun to get some land and raise some animals. Alpacas seem popular, they’re adorable, so why not get a pet alpaca?! Since that’s what we primarily raise on our small farm, let me give you a little insight into what you are getting yourself into.

Before I jump in, can I give you some idea of what we’ve been through in the last 7 years? We’ve had 6 cria born on our farm, the first about a month after getting our alpacas. We more-or-less rescued them from some people who did not have enough room or the resources for them. We had to scramble a bit before that baby came, but the infrastructure was all in place, since my dad had farmed for all those years. Everything went amazingly well for that first one, Daisy. One year later, our cria died at ten days old, in part because of our lack of experience. It hurts to admit that, and we will never know the true cause, but I definitely feel like we could have done more. We had to bottle feed one little fella for 8 weeks — multiple times a day we made up bottles, warmed them up, and took them out to him. After 8 weeks, he learned to nurse! We had one cria born out of season (in October, way too late for Canada) because our farm-sitter made a mistake. Our elderly female passed away last year and it was so difficult. So I do know what I’m talking about and I’d like to enlighten you a little bit on what it means to raise livestock, because make no mistake — alpacas are livestock, not pets. And if you have never done this, you’ll need to make some changes to your life and your thinking.

First of all, to think like a farmer you need to put your animals’ welfare first. If it is 2 AM and you need to get up to check on them, you do it. Without hesitating. If you need to learn how to give needles to your animals, you do it. If you need to clean out a stinky barn, you do it. You no longer get to behave selfishly and you can’t complain if something is dirty/stinky/yucky/uncomfortable/difficult. (You CAN complain about the weather if you like. That’s a thing farmers do! 🙂 Raising animals is not something to do on a whim. It’s not always fun. It is rewarding, but it is bleepin’ hard work.

You’ll need to learn many new things; be prepared for that. Be prepared to feel foolish, out-of-your-element, and overwhelmed. Be prepared to make those hard decisions, like whether a minor injury is something you can manage yourself, or whether you need to call the vet. Sometimes, you’ll need to make these decisions fast, drop all your other plans and go.

Your animals will need you to care for them 365 days a year. You can’t take off on a whim or go on vacation whenever you want. You’ll have to spend some time training a reliable, responsible person to look after your animals for you. We’ve only been off the farm for an overnight period twice in seven years. (We do love it and don’t find this a hardship.)

Be prepared to spend money. If you have to buy feed, really be prepared. Their health depends on you feeding them well. Think about it — if you were someone’s captive with a limited area/ability to get your own food, wouldn’t you want something healthy and good-tasting given to you? You can’t just feed moldy hay because you are lazy or can’t afford better. You have to find a way to get something better. That’s part of the reason we make our own hay, but that is a whole other ball of trouble some years! Be prepared to spend money on a vet, and don’t complain about it. Again, you are their caretaker. If they need a doctor, get them one. Buy a horse trailer if you have to — and a vehicle big enough to pull it — so that you have that independence. If you can’t get your own horse trailer, find a good neighbour who can lend you one (which is not as good, since you’ll have to rely on them). Some vets will do house calls but it is better to have your own transportation. Save up a pot of emergency vet money (a thousand dollars might be enough) so that you don’t have to deny them the care they need because you are broke. You can save money on some things by being resourceful — like making your own alpaca coats or hay feeders instead of buying them — but don’t skimp on feed or medical care.

One more note on feed and land: make sure you have enough. In most areas, one acre is not enough for 3 or 4 alpacas (a starter herd). They need grass to graze, so if you are somewhere arid, reconsider raising livestock as a hobby. If you are somewhere very hot and humid, alpacas may not be your best choice. That’s a far cry from their original habitat of cool and dry mountain plateaus. Check with local farms to see if the amount of land you are planning to get will be enough. And ask what type of fences they have, because you will need those too.

Raising livestock of any kind requires a cool head and big heart. You are probably going to fall in love with your animals. And then one day, they might be too sick to save and you’ll have to say good bye. You can’t not make the decision. Your cool head must prevail and you can cry later.

You’re going to have to be fairly organized, in general. You’ll have to know how much feed you have and buy more before you run out. In the case of alpacas, you can’t change their feed too quickly, so if you can’t get what you used to feed, you need to know that early enough that you can blend their food to make it a gradual change.

You can’t have any crippling vices like alcoholism, a gambling addiction or a disabling, chronic illness. You need a second person/team of people to help when you are occasionally sick — because animal care and feeding cannot be paused for you to get better. It is infinitely rewarding to take care of animals, raise them and watch them grow, but there will be personal sacrifices.

A few specifics for alpacas: I suggest you get a few females to start out. Three or four is ideal. Make sure you have their shelter/barn, water, feed and vet care all worked out before you get them. Keep them for a couple of years before you decide if you are ready to breed them. Learn everything you can about breeding before you start that journey. If you prefer to get only males, you may need to get some or all of them castrated. Find a vet who can do this. Males need much more room than females, because they’ll chase each other more.

Animals are smart and alpacas are some of the smartest. You’ll have the fun job of trying to figure out what they are trying to tell you, or what their behaviour means. Once you get to know them, by spending time with them and watching them, you can usually figure out what’s going on and why they are acting the way they are!

I’m sorry if I sound like a know-it-all. I don’t know it all. Some of the advice I’m giving we learned the hard way, ourselves. Thankfully, we had a nearby alpaca farm that helped us when we didn’t know what to do. I hope you can find one too — you can try Facebook or Openherd.org.

To summarize — Raising livestock is a fantastic adventure and huge opportunity for personal growth. Model yourself after successful farmers and be resourceful, smart, calm, independent, patient, curious, open-minded, hard-working, grateful, always do your best and don’t complain. I promise you, the hard moments will be mixed with plenty of beautiful ones.

All the alpaca posts

Following

The other night, I was driving home from work in the snow, on a highway in the country, carefully watching the road and following the tracks of the vehicles that had gone before me. The roads weren’t great, with a slippery layer covered in snow and not very many people had ventured out yet. Everything was going fine until I noticed the tracks I was following go right into the ditch. The vehicle had been pulled out already and I drove on.

The same can happen in life, when we choose to follow someone. We follow people on Twitter, Facebook, and a host of other social media sites, but we also follow brands, fashions, religions, philosophies and society. Most of the time, it goes well; we keep up to date with the latest news and feel like we’re in-the-know.

The problem arises when you follow someone/something or a set of ideas blindly. If I had followed the tracks of that vehicle that had hit the ditch, I would have ended up there too. Luckily, I could also see the edge of the road, other vehicle tracks and occasionally, signs and reflectors that mark intersections. In a split second, I compared the tracks veering off to the right with all the other inputs I had and steered my car to stay on the road.

If you adopt an idea, become a passionate follower of a certain person, or take one side of an argument without ever looking around at the other sides, the environment around you, or other signs of the times, you are very likely to follow that idea or person right into the ditch. Following blindly is dangerous, no matter what the situation. You have to look up to notice that the tracks you’re following are veering toward danger. You have to compare those tracks to the road to see that soon they won’t be on it.

Now maybe, the road you’re on isn’t one you want to stay on. Maybe you want to be in the ditch. That’s great, if you make a conscious decision that the way of the masses is no longer for you. Just don’t follow someone or something down a narrow path without making that decision.

Following in the fog

When I walked across Baffin Island, one of the days was very foggy. It was ice fog, which is similar to regular fog, but the air is so cold, the water droplets are frozen.

One morning, we awoke to ice fog and snow. It was cold and the sky was white. We could barely see the mountains we were camped beside, and could not see even a hint of the far side of the valley.

We started walking out into the valley, away from the mountain range. It was a whiteout. I was somewhere in the middle of the group, snowshoeing single file as if in a giant snow globe. As we walked, I could see that our line was curving. We weren’t going straight, and pretty soon, we would be walking back UP the valley the way we had come.

I caught up to one of our guides and mentioned this. She called the group to a stop and went to talk to the leader. He had not noticed the curve in our track, because there were no reference points in the fog and since he was at the front, he didn’t see the curving line of everyone following. He assumed his track was perfectly straight.

He called our Inuit guides on the radio and asked them to lead the way, and they did so expertly without hesitating. They knew this landscape even in the fog. We followed their snowmobile track the rest of the day.

When you can’t find your way, ask an expert for help. Why expend energy and time going in circles — or the wrong direction entirely — when an expert can help so easily? Why beat yourself up for not knowing something you never learned? Why struggle to cope when an expert can give you tools to help you figure it out?

When you are the one leading, remember that you can’t see the line of people you are leading unless you stop and check on their progress.

Following a cat

Sometimes, I go for walks on the trails in the bush behind my house. Most of the time, my dogs and one cat, Sammy, like to tag along. It’s fun to go exploring, especially if you’re a dog! Sammy is unusual — I’ve never had a cat that liked to come on walks, but he does. He sometimes struggles in the snow, but he is such a little trooper. One time, I could see it was really hard for him and it was also quite cold out, so I turned around and led him back to the house so I could let him in. What a guy.

Lots of times on the trail, I’ll pause to look around and appreciate nature and Sammy will pass me on the trail. That makes him the new leader, since my trails are too narrow to walk side-by-side. Sometimes Brown Dog is the leader, and he is great, although he does walk pretty fast and it can be a challenge to keep up! But when Sammy is leading, he’s the worst. He’ll stop to scratch his cheek on a branch. He’ll stop when he hears a noise. He walks really slowly. He’ll stop for no reason at all. I love Sammy, but he makes a terrible leader.

This can happen with people too. They can be lovely, wonderful people but not the best leaders. They can be intelligent, interesting or revolutionary, but not good leaders. They could be rocking the status quo, but is it in a good way? Just because someone gets media attention or is elected by a population does not make them a good leader. Just because an idea is spreading like wildfire doesn’t make it a good one. And if you realize it, you don’t have to keep following.

When you are leading a cat or anyone who is struggling, stop and give them time to catch up. If you can see they won’t make it, do whatever you can to help. When you are leading, you are responsible for them. When you are the one following, you can always decide to stop. And you’ll have to stop plenty if you are following a cat.

I hope you’ve enjoyed this post! It’s somewhat in the style of my Tiny Books on Big Ideas. You may want to check my books out. 🙂

O Holy Night — Merry Christmas

The last several years, I’ve been been blessed to sing in a Christmas Eve service/event. Some of the early years were stressful as I had to learn new songs, new harmony parts and so on, but it was also quite a bit of fun. In years past, we’ve had a proper band — a professional pianist, drummer, guitarist, and bass player. That is also fun but stressful, since I am not used to running a rehearsal with a full band and a time crunch. I’d love it if rehearsals could just go as long as necessary, but there is usually a deadline.-+

Let me share with you a special song that I always sing. It is my version of O Holy Night, with lyrics rewritten to reflect on my time living in the Northwest Territories. I have nothing against the original version per se, but this was my experience with a holy night, serene, powerful and life-changing.

O Holy Night

(Lyrics by Teresa Griffith)

O holy night. The stars are brightly shining.

It is the night of my spirit’s rebirth.

Out in the woods, the river running by me,

The northern lights stole my breath, sang my worth.

A thrill of hope, my weary soul rejoices

For overhead, a mystery unfolds.

A-mong the trees, I hear the angel voices.

O night divine, O night of northern lights.

O night divine, O night, O night divine.

O holy night, O how the lights are dancing.

In awe I stand, barely able to breathe.

Awesome to see, somehow they speak of glory,

and love and infinite possibilities.

How can it be? Phenomenal pure beauty,

For in my heart, a mystery unfolds.

A-mong the trees, I hear the angel voices.

O night divine, O night of northern lights.

O night divine, O night, O night divine.